HOME » WELDING / FABRICATION

| CNC / Engineering Services |

| Welding |

| Assembly |

| Sheet Metal |

| Press Work |

| Benches & Special Purpose Trolleys |

| Tube Bending |

| Tube Piercing |

| Finishing / Plating / Spraying |

| Other Services |

| CNC / Engineering Services |

| Tool Making & Prototypes |

| Architectural Metalwork |

| Social Distancing Screens |

| Latest News |

Our latest XYZ 1020 VMC is fitted with OMP 40 Job and Datum setting probe and TS27R standard tool setting and broken tool detection…. |

Welding / Fabrication Services

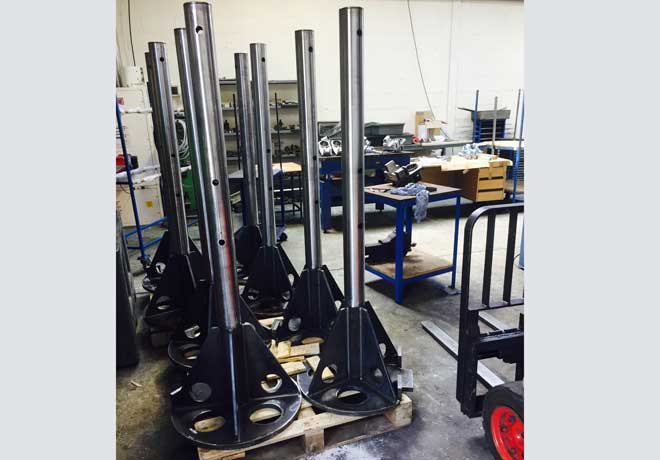

Globe Tooling Ltd offers a full in house welding and fabrication service using both MIG and TIG welding.

Globe Tooling Ltd have the ability to weld mild steel, stainless steel and aluminium using customers production Jigs and Fixtures or in-house tooling. Our services include production welding to customers drawings & specifications, design and manufacture of gates, railings, structural steel fabrication, balconies, balustrades, safety bollards, up & over mezzanine gates, purpose built trolleys, workstations, benches and pressure tested vessels.

We are also able to undertake all secondary operations including drilling, tapping and machining.

![]()

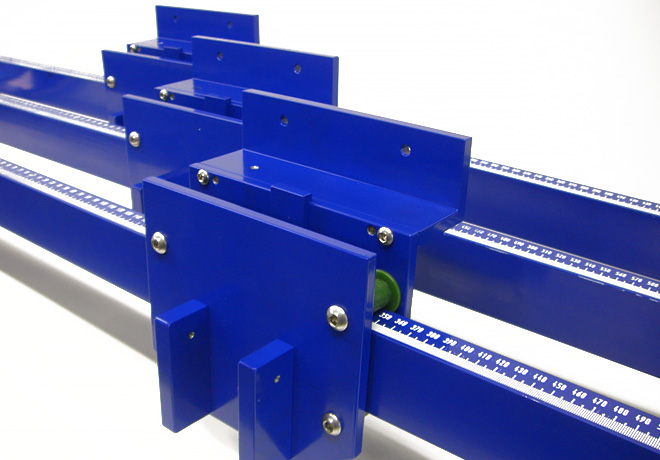

Globe Tooling Ltd are adept at both mechanical and electrical assembly and testing. We carry out inline inspection prior to boxing and can use free issue parts or in-house manufactured components. We offer a full assembly package from Manufacturing, Finishing, Assembly, Testing and Boxing right through to delivery direct to the end user or Customer.

![]()

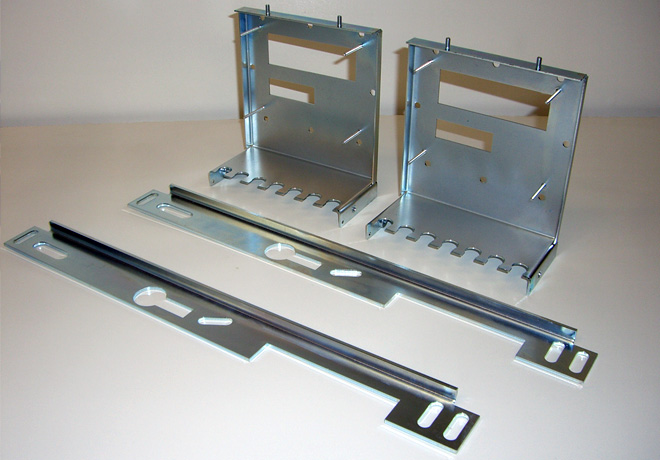

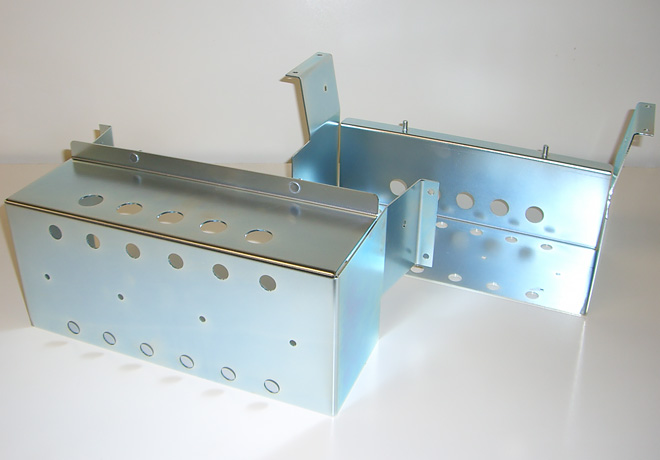

Thicknesses can vary significantly when it comes to sheet metal, therefore knowing how to work with sheet metal is integral to being a successful engineering company. Here at Globe Tooling Ltd we have numerous machines that allow us to cut, shape and punch metal sheets to meet all of the client’s needs. With three CNC Milling machines in our ever-growing arsenal and the wealth of welding experience we can not only; accurately and swiftly fulfil any specification but also provide a neat and trusted welded finish. Meaning from start to finish, you are guaranteed a top quality product.

![]()

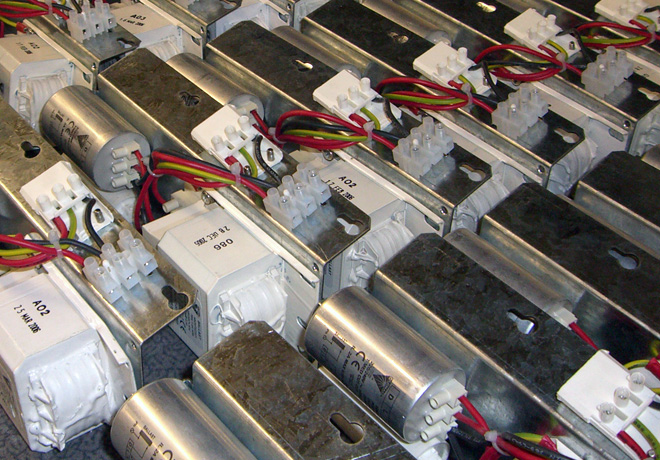

Our busy press shop is equipped with various power presses giving us the flexibility to produce many different components using the customers tooling or our own in house tooling. Small medium or high volume batch runs can be achieved with various secondary operations, drilling, tapping, riveting, welding and assembly. Various finishes can be achieved, please see our Full Finishing Services.

![]()

BENCHES AND SPECIAL PURPOSE TROLLEYS

Globe Tooling Ltd have designed and manufactured a multitude of special purpose benches, trolleys and storage solutions to suit numerous industries and their specific needs. Six Sigma, Lean and KanBan projects can all benefit from purpose built work stations, trolleys or assembly line feeding solutions all of which we have designed, manufactured and installed.

Our welding experience and structural knowledge along with our tooling programmes and assembly jigs mean we are able to create both safe and comfortable working solutions bespoke and cost effective to our customers.

Benches and trolleys can incorporate lockable hazardous waste, tooling cabinets, shadow boards, bespoke louver racks, lighting and can be finished in various materials to suit your needs.

Globe Tooling Ltd has an in-house Mandrel Tube Bending Machine with the ability to bend both square, round and oval tubes. Globe Tooling’s In-House CNC Machine shop are able to offer secondary operations including threading, welding, drilling, tapping, machining. Tube Bending is a very cost effective and accurate way to produce products for various industries.

Examples of Tube Bending are: –

Forecourt Flower and Newspaper Stands

Point of Sale Stands

Petrol Pump Stands

Golf Trolley Parts

Pharmaceutical Hangers

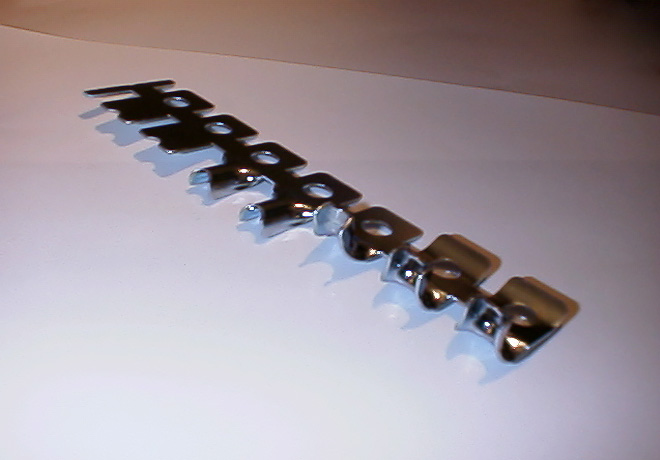

Tube punching, piercing and slotting is generally used on high production quantities.

With over 40 years of experience in the press tool making industry Globe Tooling Ltd have a vast amount of experience in Tube Piercing in both square, round and oval section, piercing and slotting tools are designed and built in-house to the customers needs. On high production work, tube piercing is extremely cost effective, eliminating the need for machining costs.