HOME » CNC BATCH PRODUCTION

| CNC / Engineering Services |

| CNC Milling |

| CNC Turning |

| Grinding |

| Wire Erosion |

| Spark Erosion |

| Finishing / Plating / Spraying |

| Other Services |

| Tool Making & Prototypes |

| Welding, Fabrication & Press Work |

| Architectural Metalwork |

| Social Distancing Screens |

| Latest News |

Our latest XYZ 1020 VMC is fitted with OMP 40 Job and Datum setting probe and TS27R standard tool setting and broken tool detection…. |

CNC / Engineering Services

Correct planning is essential for stability and longevity

CNC MILLING

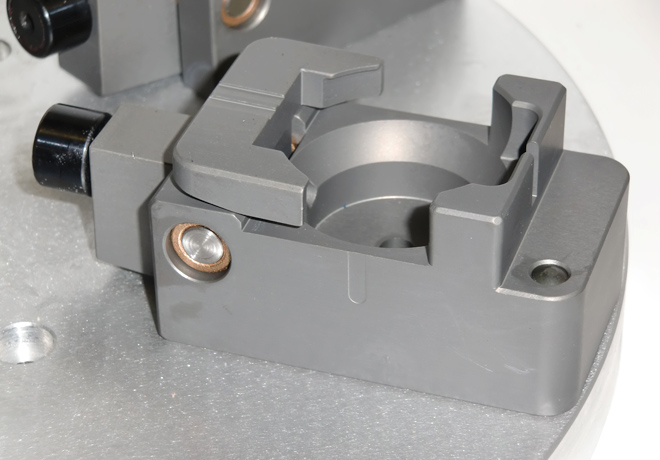

Globe Tooling Ltd has established a reputation for excellent standards in precision milling. We are able to produce precision production components using CNC milling, 3 d milling, manual prototype milling and 4th axis machining. Continually investing in the latest 3D Cad Cam software and VMC Machining Centres enables us to deliver high quality parts on time and on budget.

All of our VMC machines are fitted with 75 series Micro loc work holding systems reducing our set up times by up to 80% and relinquishing the need for bespoke milling jigs and fixtures altogether reducing costs and time.

![]()

CNC TURNING

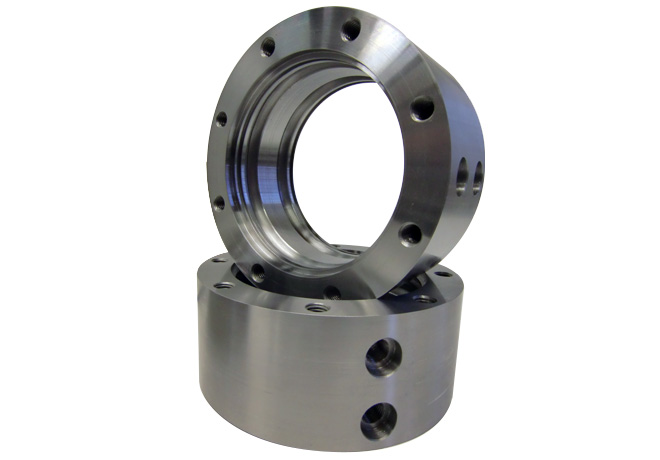

Globe Tooling Ltd are able to offer a precision turning service for small batch production and one off prototypes in a vast range of materials including Stainless steel, Aluminium, Titanium, Bronze, Brass, Tooled Steels, and Plastics. Investment into our CNC turning capabilities, ensure we supply parts to the highest quality at a competitive price.

Globe Tooling Ltd can offer both flat bed and cylindrical grinding used in the manufacturing of Core Pins, Dies, Progression Tooling, Repair and Regrind of Press Tools and Extrusion Dies. Grinding is an integral part of our tool making capabilities.

![]()

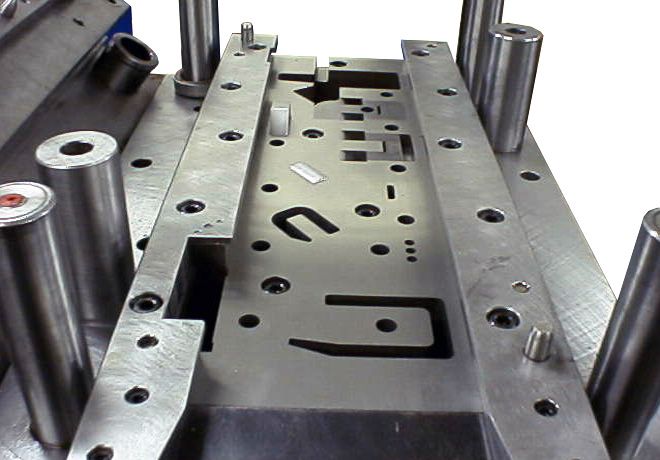

WIRE EROSION

Globe Tooling Ltd have recently invested in a new Agie Charmilles Cut 20P Wire EDM Machine which enables us to wire harden tool steel and a variety of alloys. The wire erosion process can be used to cut a wide range of materials including Stainless, Titanium, Hastelloy, Inconels, Tungsten Carbide, Aluminium Alloys, Graphite and Copper.

Wire erosion is a non-contact process which enables us to create very fine detail without distortion or stress being imparted into the work-piece.

Because there is no tooling to wear out, wire erosion offers superior repeatability and consistency on every part manufactured to a tolerance of up to 5 microns. All programming is carried out on our 3D CAM software on or off the machine.

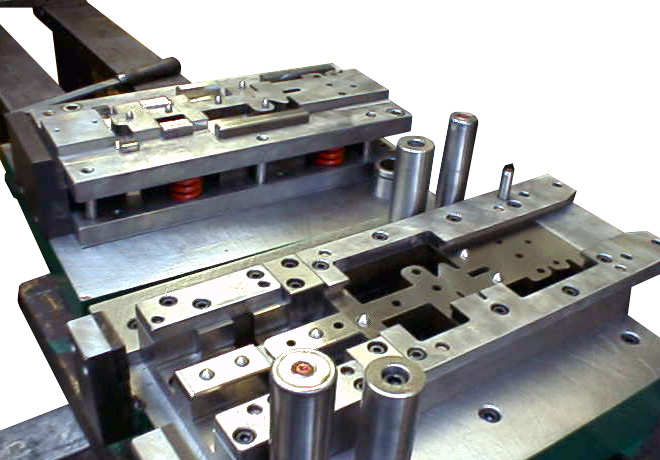

Wire erosion can be used for one off prototyping, production batch work and tooling. We are able to operate unmanned in a lights out environment for production job and keep very high tolerances. Wire erosion is the perfect machine for Punches, Dies, Punch Plates Extrusion Dies or hard to machine prototype shapes.